Browse Columbia’s Aluminum Window Products

Aluminum Windows

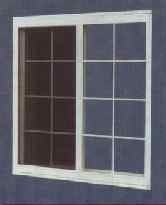

Columbia’s aluminum windows are available in both standard and thermally improved options. Combining form and function, our portfolio of aluminum window products offers a uniquely broad spectrum of options to meet the needs of any new construction or rehabilitation project. Builders and architects have specified aluminum windows and doors because of its overall strength. Aluminum windows and doors are popular because they do not have many expansion or contraction issues over time. They will not rust or rot. Our aluminum products have a baked-on finish. Most aluminum windows that are manufactured today have a thermal break in the extrusion that improves their efficiency. Most of your heat loss is threw your glass. If you want a more efficient aluminum window you will need to add Low E or bronze solar tint. The Columbia aluminum thermal break primary window is designed for single dwelling through multifamily units. Our aluminum windows are manufactured in standard sizes for new construction, or custom sizes for retro fit applications. Our aluminum windows with thermal break frames are truly thermally efficient window system. Our aluminum thermal break windows are designed for the new home builder, the remodeling contractor and the home owner. The home owner will have a durable, maintenance free easy to clean aluminum window.

Columbia also manufacturers a line of non thermal break windows which can be used for pole barns, machine sheds or garages. This product line of aluminum windows are offered with single glazing or insulated glass and with or without integral “J” channel.

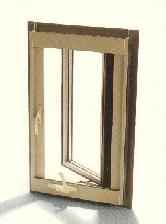

Columbia also manufacturers a thermal break aluminum casement widow for new construction or replacement applications. Our aluminum casement windows has heavier hardware than other casement windows in its class. The operator has a test rating of 80 pounds; the standard of the industry is only 40 pounds.